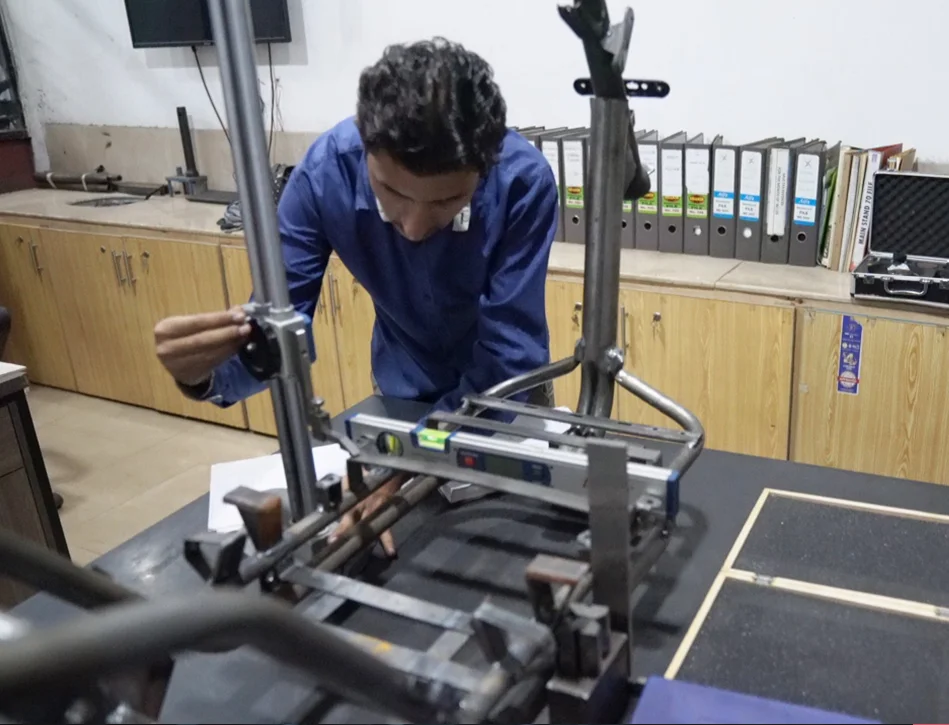

3D SCANNING & INSPECTION

We employ high-tech, user-friendly equipment like the CMM Arm to deliver precise 3D measurements of objects at high speeds. This tool offers 7-axis freedom and unmatched scanning precision.

- CMM Arm Model: Nikon MCAx 20+

- Measuring range: 2.0 meters

- Laser Scanner:

- Max Output = 5mW x 1.0mW

- Emitted Wavelength = 660nm & 635nm

DESIGN DEPARTMENT

Our Design Department is at the heart of innovation, where creativity meets precision. We transform ideas into both functional and aesthetically pleasing designs using state-of-the-art tools and technologies. Every design is meticulously analyzed, prototyped, and refined to meet the highest standards of quality and functionality.

DEVELOPMENT SHOP

CNC Milling

Our CNC milling services provide exact machining for dies and tools, offering both small and large batch operations with extreme precision. We specialize in producing components with tight tolerances, using various machine types for flexible production.

CNC DEPARTMENT

We specialize in high-precision laser cutting, delivering clean edges and intricate designs with exceptional accuracy. Our advanced technology ensures consistent results across a wide range of materials, enabling efficient production and minimal waste. Each cut is optimized for durability, precision, and seamless integration into the final product.